|

The Solid Model is only available for Milling operations when using the Backplot Window option. |

In this section, the Backplot function Solid and the simulation of the Solid Model are described.

|

The Solid Model is only available for Milling operations when using the Backplot Window option. |

|

|

The Solid menu. |

Shows / Hides the solid model.

Click on this icon to toggle between the toolpath view and the Solid visualization with toolpath.

Creates a solid from the current view.

Click this icon to regenerate a solid model of the workpiece, based on the settings specified in the Solid Setup. You can select if the toolpath should be shown or hidden when a solid model is displayed.

When this option is enabled, the program will be checked for collision during dynamic simulation. The collision check options are activated in the Solid Setup dialog.

When a collision is detected, the simulation stops one block before the collision - both in the graphical simulation and the NC program.

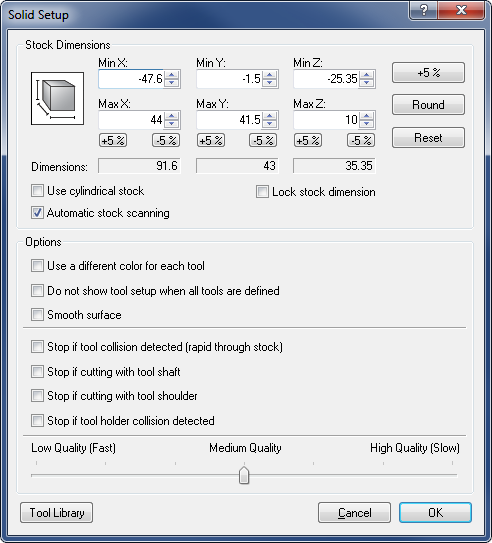

Click on this icon to configure the Solid Model and the options for the solid simulation. The specified stock dimensions are the minimum and maximum X, Y, Z values in your NC program. If you want to increase or decrease the stock dimensions to get a much more even toolpath, then click one or several times the corresponding button (+5% or -5%) to obtain the desired dimensions. Use the button Round to round off stock dimensions.

|

|

Solid Setup dialog for milling. |

If the Automatic stock scanning option is enabled, stock dimensions will automatically be scanned from the NC program file. To specify stock dimensions within an NC program, add a comment with the following layouts:

|

Decimal numbers are supported. The +/- sign is required to be in front of each value. Input fields are disabled when Stock dimensions are found and Automatic stock scanning is enabled. |

The Lock stock dimension option allows you to lock the stock dimensions to a machine. The stock values will be saved in the machine settings to make them available for used in other NC programs. This is especially useful when testing different NC programs on the machine.

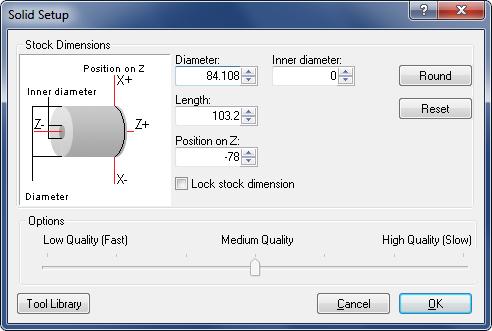

Click this icon to configure the Solid Model for the Solid Animation. The specified stock dimensions are the maximum values in your NC program, and the Position on Z is calculated on basis of these values. Use the button Round to round off stock dimensions, click Reset to revert to the stock original values.

|

|

Solid Setup dialog for turning. |

The Lock stock dimension option allows you to lock the stock dimensions to a machine. Checking this field saves the stock values in the machine settings, so they are available for used in other NC programs. This is especially useful when testing different NC programs on the machine.

|

The stock dimensions are locked temporary and will not be available when CIMCO Edit v7 is restarted. |