|

|

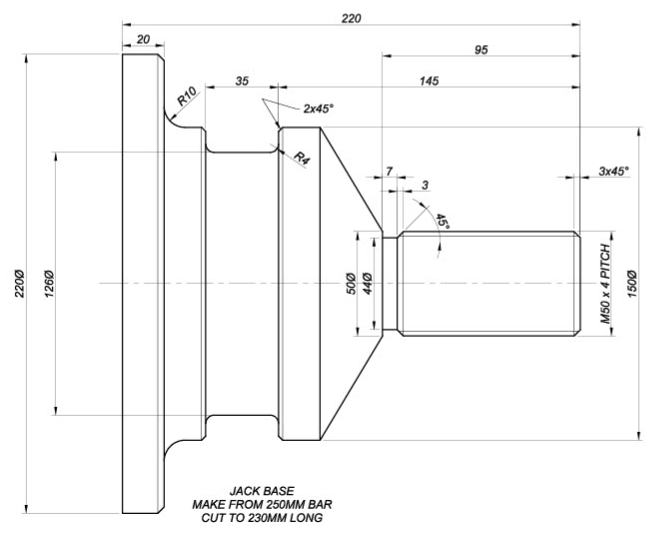

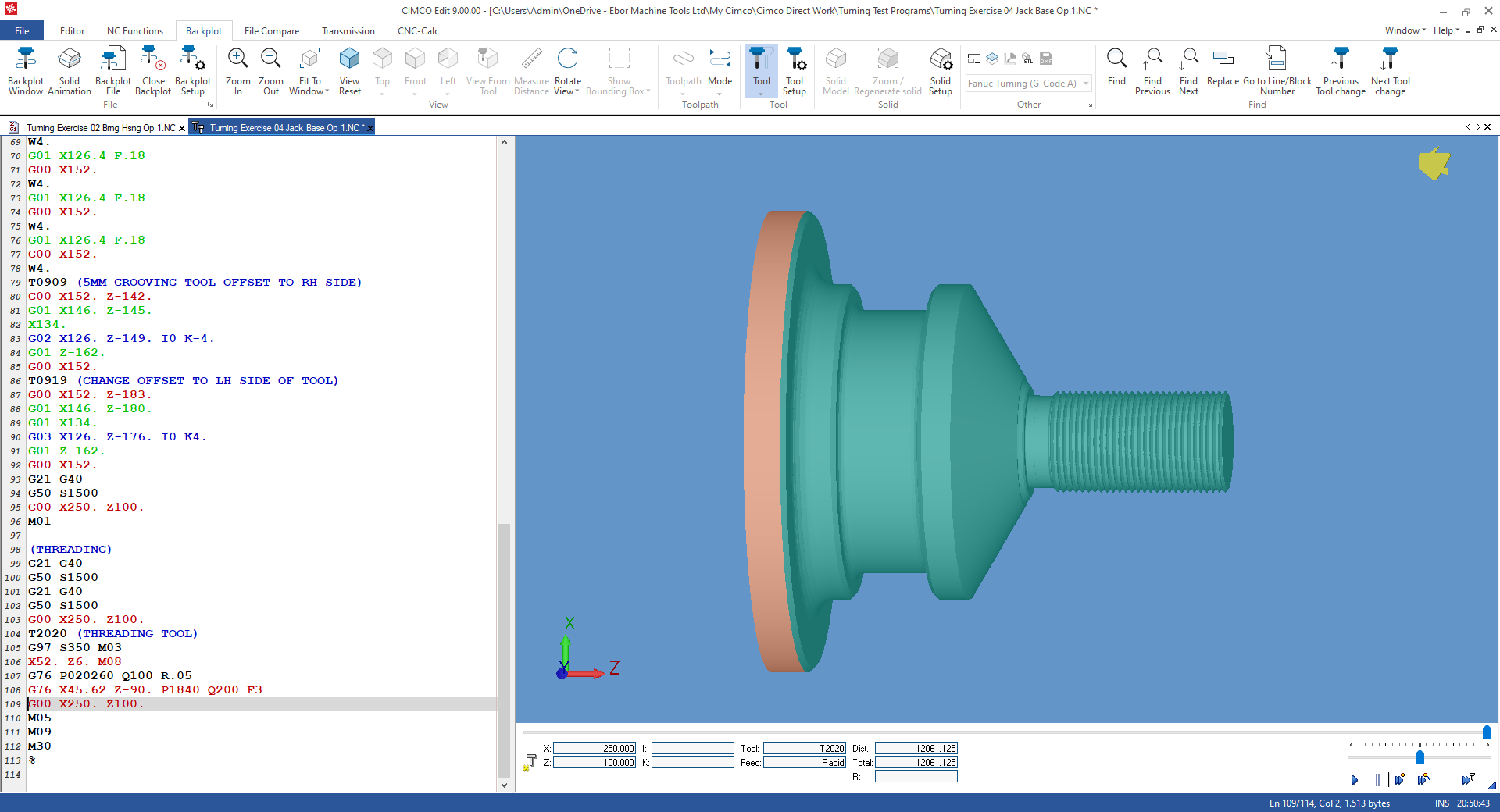

The Jack Base drawing will introduce the additional programming features of grooving and screwcutting. The part will be faced, and profile turned using G71.

A 5mm wide grooving Tool will rough and finish the undercut for the Screw Thread and also the 35mm Groove. The grooving will be programmed using two offsets. The first offset will be for the right-hand corner of the Tool. This way we use the drawing dimension on the right-hand side to complete half of the groove and then switch the offset to the left-hand side of the Tool and use the drawing dimensions to complete the other half of the groove. We will plunge into the 35mm groove to rough it out with multiple cuts then finish by profiling first the left-hand side profile then the right-hand side right hand side profile, again changing offset to allow for the tool width so as to program using the drawing dimensions. The undercut can be finish profiled with the right-hand tool offset only but the programmer must allow for the tool width in the Z axis programming.

We will introduce the Fanuc Screwcutting Cycle G76 for the Threading on the M50 x 4mm pitch Thread.

All the programming here has been carried out by entering CNC code into the editor and testing with the toolpath Backplot and Solid Animation. We will move onto using the CNC-Calc CAD/CAM in another lesson.

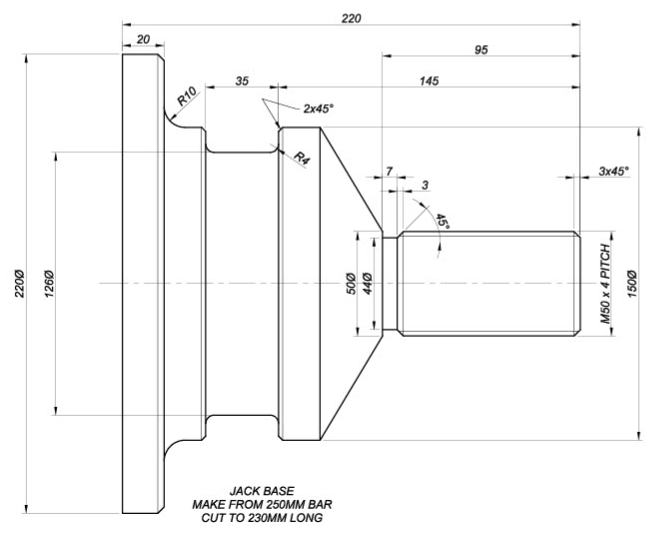

See below the basic coordinates entered into the Editor and tested with toolpath Backplot. Notice the plunge cuts for roughing the groove and the Undercut. See the W incremental moves to step over for the plunge cuts.

|

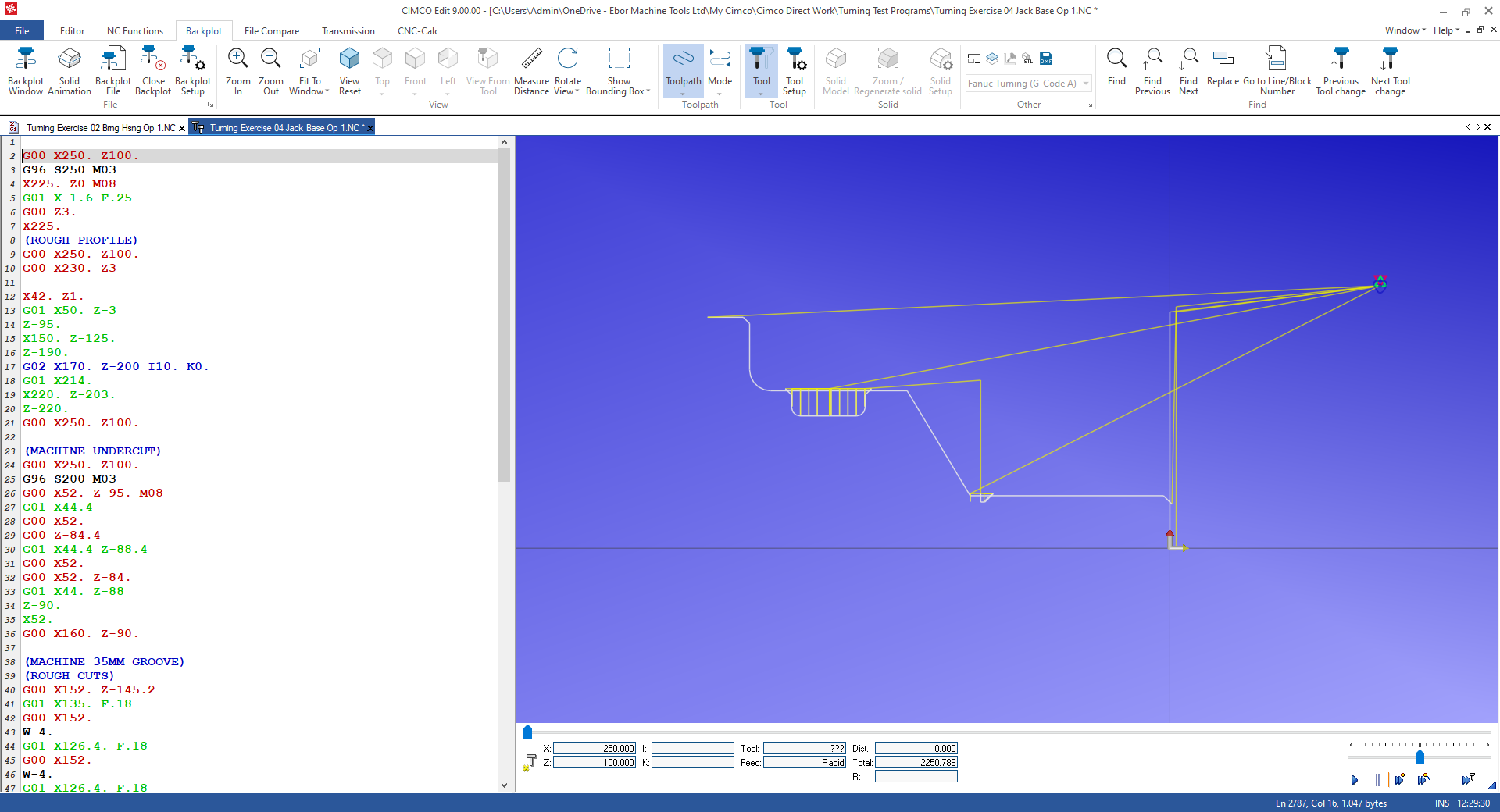

Now add the other program features as before to achieve the roughing and finishing cycles and other information to create a working program. If you are not sure about the code go back to the previous sample.

|

| T0101 | (TOOL CHANGE ,SELECT TOOL1 OFFSET 1) |

| G97 S1000 | (START SPINDLE FORWARD AT 1000PRM) |

| G00 X51. Z5. | (MOVE TO START POSITION-RAPID) |

| G76 P020060 Q100 R50 | (THREAD CYCLE LINE 1) |

| G76 X46.318 Z-93. P1841 Q200 F2 | (THREAD CYCLE LINE 2) |

| G00 X45. Z5. | |

| M30 |

Description of threading cycle above:

Thread cycle G76 line 1:

P020060 = 02

No. of Finish Passes, 00 – Runout, 45 degrees at the end (01=1 pitch), 60 – Inc Angle of Thread

Q100

Minimum depth of cutting pass 100=0.1 mm (No decimal point)

R.05

Amount of finishing allowance 0.05mm

Thread cycle G76 line 2:

X = Minor Thread Diameter

Z = Length of Thread

P = Threading Depth (1.840 = 1840) (No decimal point)

Q = Depth of First Cut (0.2 = 200) (No decimal point)

F = Thread Pitch

Thread details:

M50 x 3 Pitch

Major diameter is 40φ.

Pitch is 4mm.

Thread Depth Calculation = Pitch x 0.61363 = 3 x 0.61363 = 1.84089

Minor Diameter = 50 – (2x1.84089) = 46.3182

When you have finished programming the Jack Base you will achieve a Solid Animation as below. The Animation shows that the program can be run on the machine with some confidence. You may need to adjust the speeds and feeds to get an optimum time and acceptable tool life.

|