|

There are several types of drilling canned cycles. For example, there may be a need to center drill some holes that may need to be drilled deeper and some long holes may need to be reamed and some may need to be tapped with a screw thread.

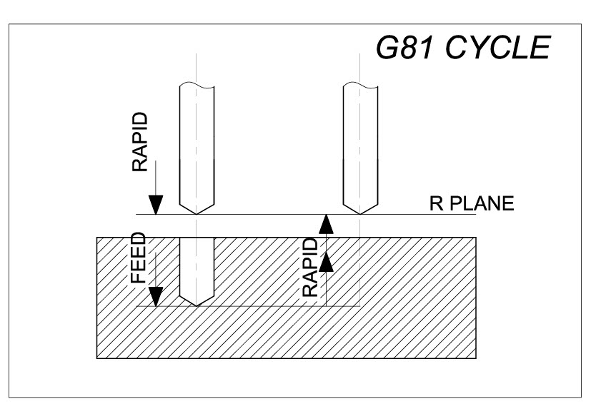

For each of these functions there is a cycle. The cycle that will be reviewed here is a G81 that is usually used for centering or less deep holes, a G81 is the same as a call of preprogrammed subprogram or sometimes called a canned cycle. When programming in the main program with a G81 there are fixed parameters to be programmed together with the G81.

|

| G81 | Drill Cycle Call |

| G98 | Up to retract height |

| G99 | Up to R plane |

| R | First reference height (close to Z0) |

| Z | Hole depth |

Program example with G81 for a Fanuc control.

| O1000 | - |

| N10 G40 G80 | - |

| N20 G28 G91 Z0 | - |

| N30 T10 M06 | - |

| N40 G90 G54 S1000 F300 M03 | - |

| N50 G00 G43 H10 Z100 | - |

| N60 G00 X10 Y10 | First X and Y coordinate to drill |

| N70 G81 G99 R5 Z-10 | A R plane height of 5mm above the surface. Drilling depth is 10mm. |

| N80 X10 Y90 | Second X and Y coordinate, cycle repeated |

| N90 X90 Y90 | Third X and Y coordinate, cycle repeated |

| N100 G80 | Cancel G81 cycle. |

| N110 G28 G91 Z0 | - |

| N120 M30 | - |

Coordinates may only be programmed without G codes between line N70 where G81 is activated and line N100 where G81 is cancelled with G80. In this program example, three holes were drilled.

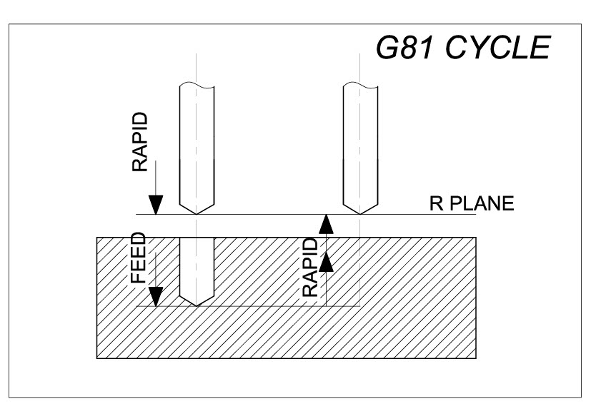

Create a program for the drawing below where you will use G81 for the holes and where you will still decide which cutting tools you want to use and which quadrant you want to program in.

|

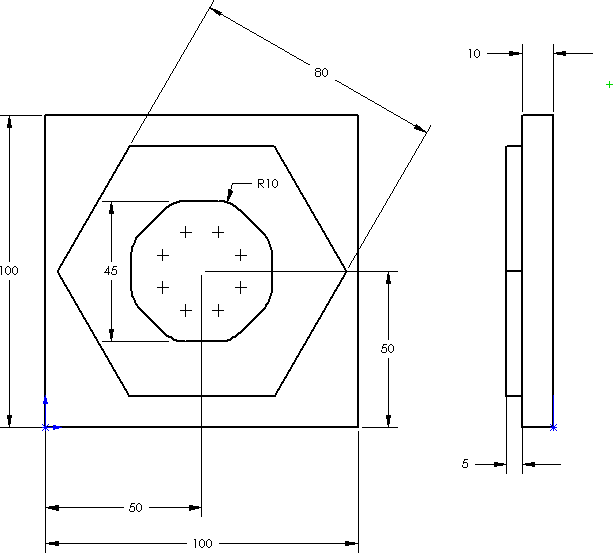

Create a program for the drawing below.

|