Radius Compensation

If the CNC control system cannot compensate for the radius of the tool, the contour of the machined workpiece will not be correct unless the programmer creates a toolpath considering the tool radius. This is because all programmed moves will take place with respect to the tool centre line. When CNC controls have automatic radius compensation, then the programmer can use the workpiece drawing dimensions and the CNC control generates a toolpath parallel to the workpiece dimension offset by the tool radius.

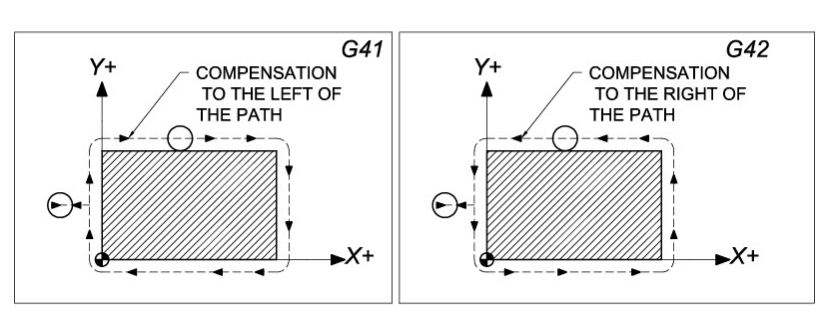

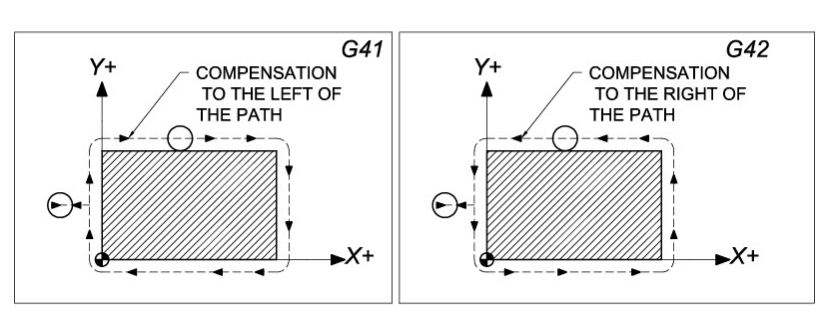

The preparatory commands G41 and G42, are used to apply radius compensation. G41 will apply radius compensation to the left of the path in the direction of travel. G42 will apply radius compensation to the right of the path in the direction of travel. When programming with G41 or G42, it is important to program so that the first move to apply the compensation has of sufficient distance to allow the CNC control to make the compensated move. For example, it could be a movement to X-20 Y-20, then a Z depth is programmed. Between X-30 Y-30 and X0 Y0, G41 is programmed or G42 with a #D value taken from the Tool Offset table for the radius of the tool.

Example program with Radius Compensation

| O1000 |

N10 G40 G80 |

N20 G28 G91 Z0 |

N30 T03 M06 |

N40 G90 G54 S1000 F500 M03 |

N50 G00 G43 H03 Z100 |

N60 G00 X-30 Y-30 Z5 |

N70 G01 Z-5 |

N80 G01 G41 D23 X10 Y10 |

N90 Y90 |

N100 X90 |

N110 Y10 |

N120 X10 |

N130 G00 G40 X-30 Y-30 |

N140 G28 G91 Z0 |

N150 M30 |

Assignment: Radius Compensation

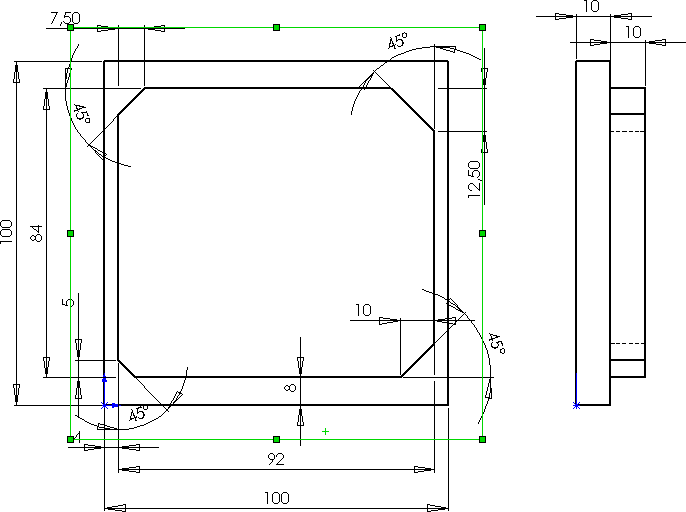

Produce a CNC program for the drawing below where the program is set in the first quadrant and the square is machined with a 20mm one-cutter. The program is written with radius compensation. You can decide whether you want to program with a G41 or G42. The direction of travel determines this.