|

|

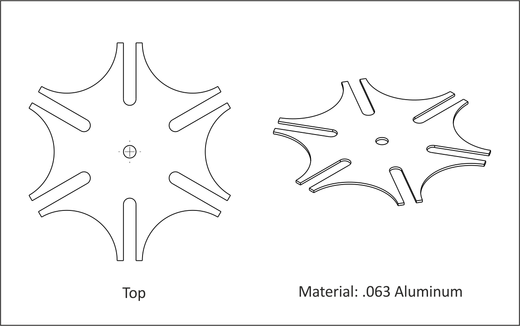

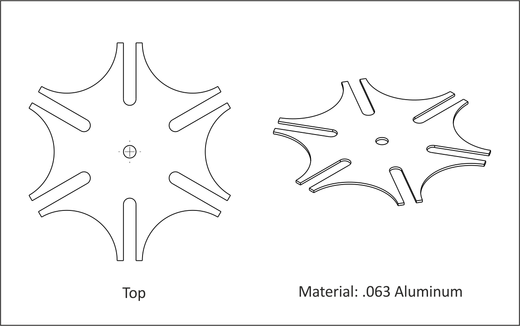

Figure A.42: Geneva Gear |

This project teaches the following skills:

Some parts can be held using double-sided tape. This eliminates the need for making a complex fixture and works quite well if cutting pressures are low and surface area is large enough to form a sufficient bond.

Aluminum and Medium Density Fiberboard (MDF) are commonly used fixture plate materials. Prepare an aluminum plate by clamping it to the table and facing it smooth and flat to form a good surface to bond to. Don't use coolant because its residue will inhibit good bonding.

To ensure a good bond with the tape, a good practice is to place a heavy weight on the part and let it set for at least 15 minutes after taping. The longer this weight is in place, the better the bond, so leave it for several hours or overnight if possible.

|

|

Figure A.42: Geneva Gear |

|

Geneva Gear: Machine Complete | ||||

|

| ||||

|

Datum: G54 XY is at the approximate center of stock. G54 Z is top of stock material. | ||||

|

Op-1 Contour |

Tool (inch) .25 End Mill |

Speed (rpm) 1800 |

Feed XY (ipm) 18.0 |

Feed Z (ipm) 9.0 |

|

Rough XY (in) 1.0 |

Rough Z (in) .25 |

Finish XY (in) 1.0 |

Finish Z (in) .005 | |

|

Stock to Leave XY (in) 0.0 |

Stock to Leave Z (in) 0.0 | |||