|

|

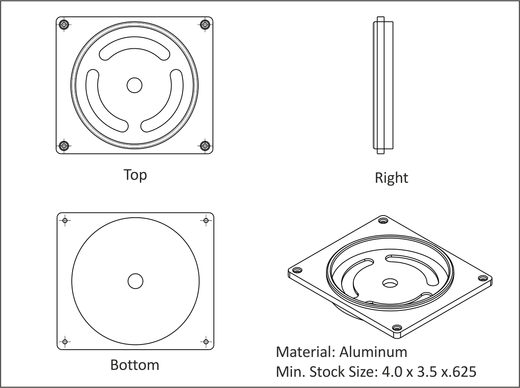

Figure A.18: Project-6, Housing |

This project teaches the following skills:

|

|

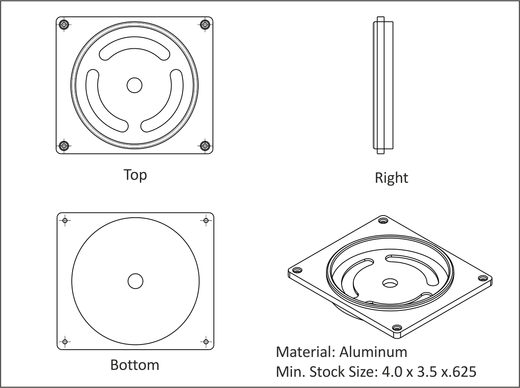

Figure A.18: Project-6, Housing |

Grip the sawed stock in the vise as shown in figure in Table A.4. Set the XY-datum off the upper left corner of the stock. Leave enough stock so the contour tool path removes material all around the part (typically .20-.05 inches from the sawed stock corner). Set the Z-datum so that the face tool removes material off the entire face of the part (typically .01 inches below the face of the sawed stock).

Machine the part using the processes and sequence in Table A.4. Select appropriate tools, speeds, feeds and machining parameters.

|

Housing: Job-1 Setup | |

|

| |

|

G54 Datum: Upper-left corner, top of sawed stock. | |

|

Op-1 Face |

Face part. |

|

Op-2 Contour OD |

Rough and finish OD of part (rectangle shape). Be sure to machine below the bottom of the OD so no flashing will remain after Job 2, but don't collide with the vise hard jaws. |

|

Op-3 Contour OD |

Rough and finish OD of round boss. |

|

Op-4 |

Rough and finish pocket to top of slots. |

|

Op-5 Slot Mill |

Rough and finish slots. |

|

Op-6 |

Rough and finish hole through center. Be sure to break through bottom by .01. This hole must be completely through the stock because it will be used to set the G54 XY for Job 2. |

|

Op-7 Spot Drill |

Spot and chamfer four holes. |

|

Op-8 Drill |

Drill clearance holes for #2-56 socket head cap screws. |

|

Op-9 Counterbore |

Counterbore with 3/16 (.188) end mill for socket head cap screw. |

|

Op-10 Chamfer |

De-burr all edges by chamfer milling with a center drill or chamfer mill. |

Flip the part about the Y-axis and grip the finished walls of the part. Set the G54 XY from the center of the through hole created in Job 1. De-burr the hole before locating its center using dial indicator, coaxial indicator, or part probe. Set G54 Z the same way as Base, Job 2 (using 1-2-3 blocks) to the top of the finished face of the part bottom.

Machine the part using the processes and sequence in Table A.5. Select appropriate tools, speeds, feeds and machining parameters.

|

Housing: Job-2 Setup | |

|

| |

|

G55 Datum: X0Y0 is the center of the hole created in Job 1. Z0 is set at the face of the finished bottom side (Z.500 (in) from top of parallels). | |

|

Op-1 Face |

Finish part to thickness. Use light cuts to prevent part from being pulled out of vise. |

|

Op-2 Contour OD |

Rough and finish OD of round boss. |

|

Op-3 Chamfer Mill |

De-burr all edges. |