Check List

Buttons

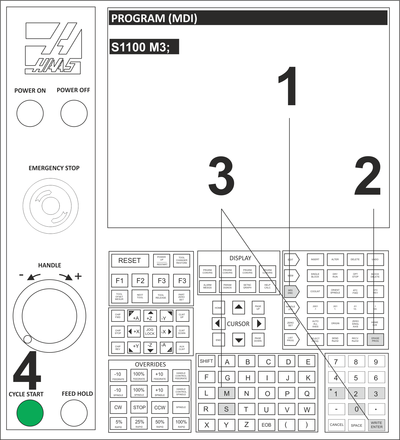

1

MDI/DNC Key: Select

![]()

2

Erase Prog: Select (to clear any commands)

![]()

3

Spindle Speed: S1100

- S1100 M3: Input

- Write/Enter: Select

4

Cycle Start: Select

- Spindle will start CW at 1100 RPM

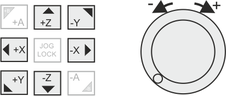

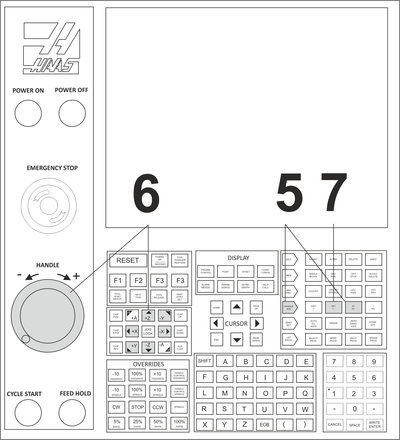

5

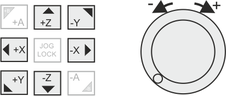

Handle Jog: Select

Jog Increment: .01

![]()

![]()

6

Jog Handle: As Needed

- Select jog direction and use handle as required to place edge finder stylus alongside the left part edge.

7

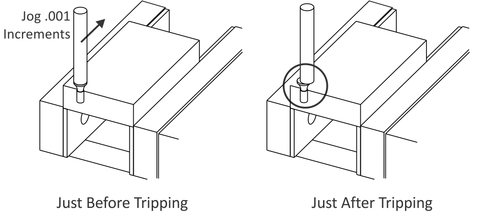

Jog Increment: .001

- Move edge finder slowly until it just trips off center as shown below.

- This places the center of the spindle exactly .100 from the part edge.

![]()

8

Jog Handle: Retract in Z

- Jog straight upward in Z until edge finder is above part and jog handle reads zero on the dial.

![]()

9

Jog Handle: Set jog direction to +X and rotate handle one full turn clockwise.

- Since the control is in .001 increment mode, rotating the dial exactly one full turn places the center of the spindle directly over the left part edge.

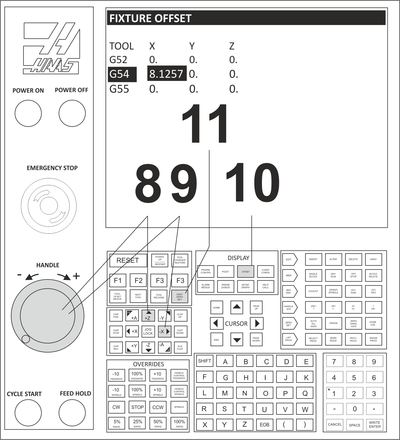

10

Offset Page: Select

- Select Offset button and PgUp/PgDn buttons until Work Zero Offset page appears. Use Arrow keys to highlight G54 (or whatever fixture offset is to be set).

![]()

11

Part Zero Set: Select

- This sets the G54 X value to the current spindle position.

![]()

|

Tips

|

The following instructions repeat steps 6-11 but for setting the Y-axis.

12

Jog Handle: As Needed

- Select jog direction and use handle as required to place edge finder stylus alongside the back part edge.

13

Jog Increment: .001

- Move edge finder slowly until it just trips off center.

- This places the center of the spindle exactly .100 from the part edge.

![]()

14

Jog Handle: Retract in Z

- Jog straight upward in Z until edge finder is above part and jog handle reads zero on the dial.

![]()

15

Jog Handle: Set jog direction to -Y and rotate handle one full turn clockwise.

- Since the control is in .001 increment mode, rotating the dial exactly one full turn places the center of the spindle directly over the back part edge.

16

Offset Page: Use arrow keys to highlight G54 field (or whichever fixture offset you are setting).

![]()

17

Part Zero Set: Select

- This sets the G54 Y value to the current spindle position.

![]()

18

Spindle Stop: Select

![]()