Check List

Buttons

1

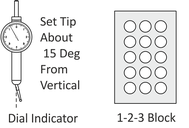

Prepare:

- Ensure tip angle of dial indicator is at about 15 degrees.

- Ensure gauge block is flat on table, no chips underneath, and not floating on coolant.

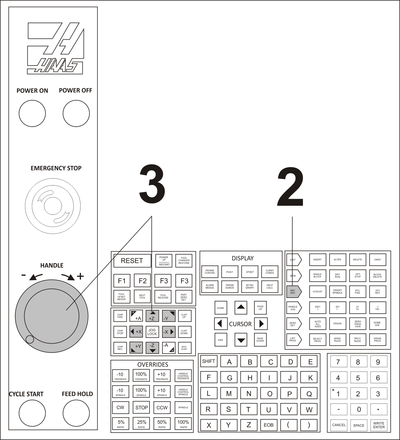

2

MDI Mode: Select

- Ensure machine is in MDI Mode

![]()

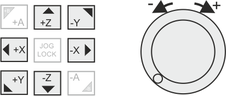

3

Handle: As Needed

- Select jog direction and use handle as required to place dial indicator stylus on top of gauge block and the dial reads zero.

Note: Machine parameter 64 (T OFS MEAS USES WORK) must be set to OFF to use this method.

4

Posit Button: Press

![]()

5

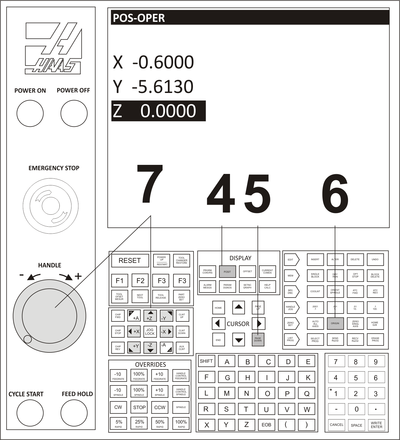

Operator Screen: Select

- Use PG DN Button (5 times) until POS-OPER screen appears.

![]()

6

Origin: Set

- Press Origin button to set Z-value on operator screen to zero.

![]()

7

Handle: As Needed

- Select jog direction and use handle as required to place dial indicator stylus on top of part stock and the dial reads zero.

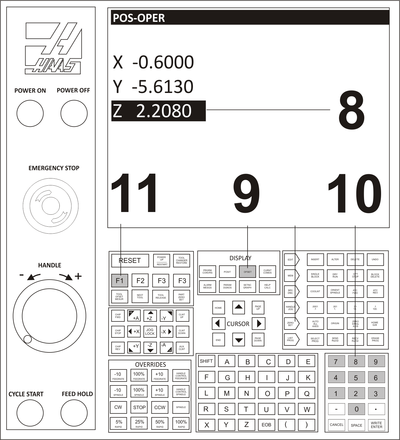

8

Operator Z Value: Read

- Read the operator Z value from the graphic area. This is the incremental distance between the top of the 1-2-3 block and the top of the part. Ex: 2.2080

9

Offset Page: Set G54 Z Value

- Press Offset button twice to get to Offsets Page

![]()

10

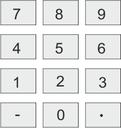

Numeric Keypad: Enter Z Value

- Input the value using the numeric keyboard.

- To set Z below the part face, reduce the value by the amount of material removed by the face cut.

11

F1 Button: Press

- Select the F1 button to enter the value input in Step #7 into the Z offset field.

![]()