|

|

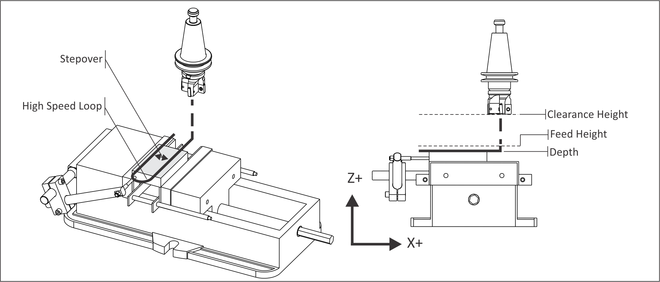

Figure 7.8: 2D Facing Toolpath |

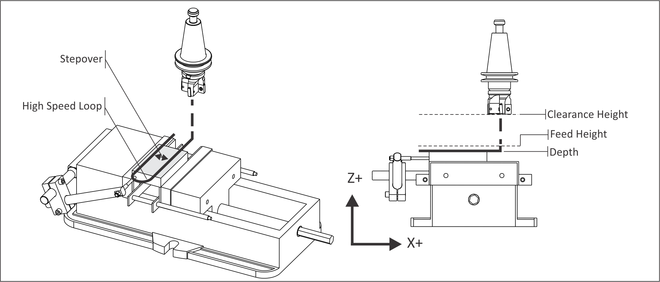

Facing is often the first machining operation. It is used to cut away excess material and finish the highest flat face of the part. Depending on how much stock is removed, several roughing cuts may be required. A smaller finish pass ensures a flat surface and good surface finish.

Use a face mill when possible for all but the smallest part. The large diameter of facing mills and multiple carbide insert cutting edges provide for very high material removal rates.

High speed loop transitions between cut passes produce a fluid tool motion that place less stress and wear on the CNC machine.

|

|

Figure 7.8: 2D Facing Toolpath |