|

|

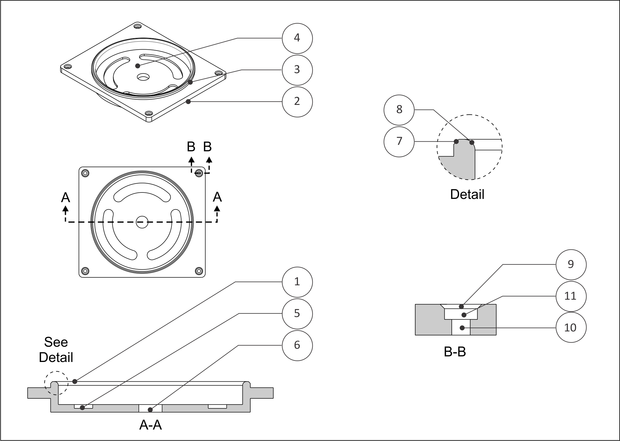

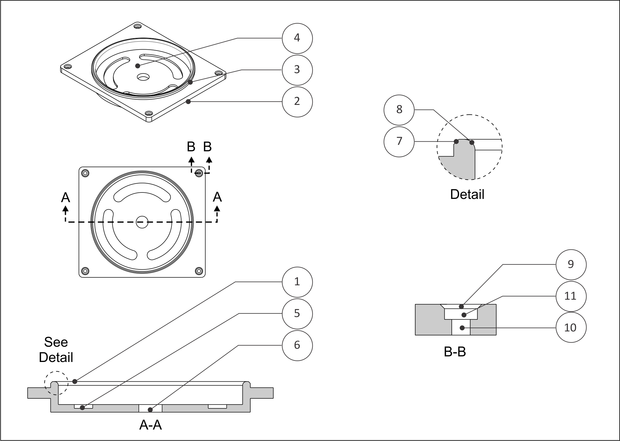

Figure 7.5: 2D Machining Features Example |

Before going further, it is helpful to understand how 2D toolpaths are classified in most CAM software. Table 7.1 lists the common 2D toolpaths by type and common use. For example, 2D contour, chamfer, and fillet toolpaths are often accomplished using the 2D Contour menu selection. Of course, where each function is located will be slightly different depending on the CAM product, but this list is appropriate to most modern CAM.

|

Type |

Toolpath |

Common Uses |

|

Face |

Face |

|

|---|---|---|

|

Island Facing |

| |

|

2D Contour |

Contour |

|

|

Chamfer |

| |

|

Fillet |

| |

|

|

|

|

|

Slot Mill |

| |

|

Drill |

Drill |

|

|

Circular Pocket Milling |

| |

|

Thread Mill |

|

It is probably obvious to you now that manufacturing is an exceedingly complex process. Many factors influence every decision and often more than one solution to any problem. Manufacturing is also a win/lose game. Either the part is right (within tolerance) or not. Don't be overwhelmed by the choices for now. Some knowledge and experience will help you settle many of these variables and greatly simplify the job of planning CNC processes.

Figure 7.5 and Table 7.2 show the operations and machining sequence to CNC mill this part.

|

|

Figure 7.5: 2D Machining Features Example |

|

Op. |

Toolpath |

Notes |

| 1 | Face | It is common practice that the first machining operation roughs and finishes to the highest flat surface of the part. Face paths overlap the sides of the loop selected. |

| 2 | 2D Contour | Machine outside loop. |

| 3 | 2D Contour | Machine outside of boss. |

| 4 | 2D Pocket | Use Pocket to rough and finish enclosed loops. |

| 5 | Slot Mill | Mill slots. |

| 6 | Circular Pocket Mill | Machine the center hole through. You could also use a Drill operation to make this hole, but would center-drill the hole first. |

| 7 | Chamfer | Use 2D Contour, Chamfer function and a chamfer tool (or center drill) to make this 45 degree chamfer. |

| 8 | Fillet | Use 2D Contour, fillet function and a corner round tool to make this fillet feature. |

| 9 | Spot Drill | Spot drill all holes to:

|

| 10 | Drill | Drill to make hole. Do this before the Circular Pocket Mill so the Spot Drill conic still exists. |

| 11 | Circular Pocket Mill | Create counterbore. |