|

|

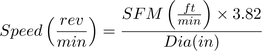

Figure 8.23: Speed Formula (Simplified) |

Speeds and feeds are calculated based on the maximum work diameter for the tool. Use the same speed formulas as for mills.

|

|

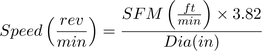

Figure 8.23: Speed Formula (Simplified) |

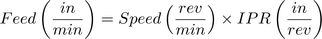

Speed is the machine spindle RPM (how fast the part turns).

SFM is the Surface Feet per Minute based on the insert manufacturers' recommendation for the material and cutting conditions.

3.82 is a constant that relates the surface feet per minute to work piece diameter.

Dia is the diameter of the tool when it first engages the material.

|

|

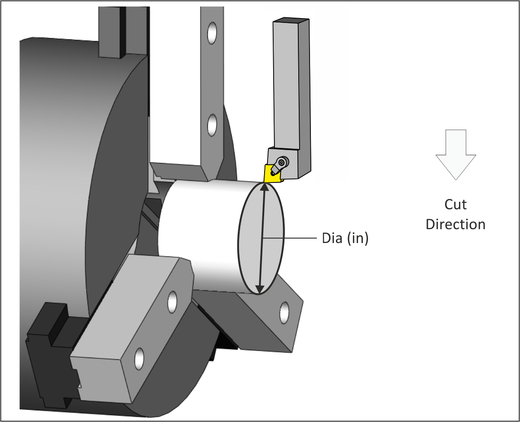

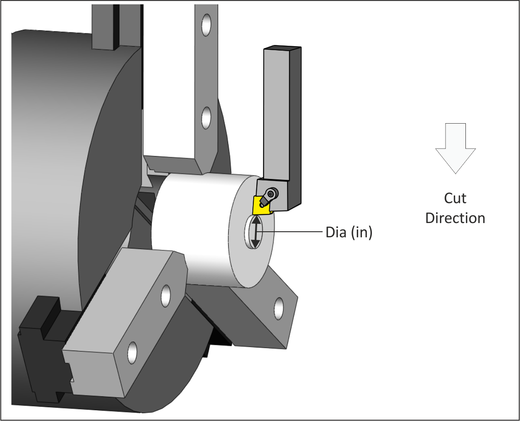

Figure 8.24: Facing Tool Engaging Material |

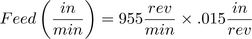

Problem:

Calculate the cutting speed for a facing operation given the following values:

| Parameter | Value |

| Part Diameter | 2.0 in |

| SFM | 500 ft/min |

Solution:

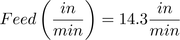

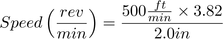

Notice that as the tool moves down the face of the part, the diameter where the cutting edge contacts the part gets smaller.

|

|

Figure 8.25: Decreasing Cut Diameter As Tool Nears Center |

To maintain a constant rate of material removal as the cutting diameter decreases, most CNC machines automatically speed up the spindle, based on how far the tool moves towards center. This constantly variable spindle control is called Constant Surface Speed (CSS) mode. It is commanded on most machines using G96 to activate, and G97 to de-activate.

G96 is preceded by some important codes, as shown in the following example:

| Block | Description |

| G50 S2000 | G50 sets the maximum spindle speed for this tool. |

| G97 S1200 T101 M03 | G97 cancels CSS so the spindle speed does not change as the turret rapids to position. |

| G00 X2.1 Z0. | Tool moves to start of cut. |

| M08 | Coolant ON. |

| G96 S1200 | CSS mode on, Spindle begins at 1200 RPM. |

| G01 X-.05 | Face part. As tool moves from a diameter of 2.1 inches to X-.05, the spindle will increase speed up to the limit of S2000 RPM. |

When invoked, you will hear the lathe spindle increase as the tool moves from the perimeter of the cut to the part center. The G50 command is important because it keeps the spindle from over-speeding.

|

Warning: All lathe chucks have speed limits based on the weight of the part and how far it extends from the face of the chuck. Do not exceed these limits. Ensure chuck clamping pressure is sufficient to grip the part based on cutting forces. Use G50 when using CSS mode to limit the speed of the spindle. |

CSS does not apply where the tool does not change its position along X. For example, don't use CSS mode for drilling or tapping on part centerline.

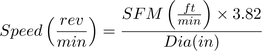

Feed is based on the speed and manufacturer' recommended Feed Per Revolution (FPR) of the tool.

Problem:

Calculate the cutting feed for tool with the following parameters.

| Parameter | Value |

| Speed | 955 rpm |

| IPR | .015 in/rev |

Solution: