|

|

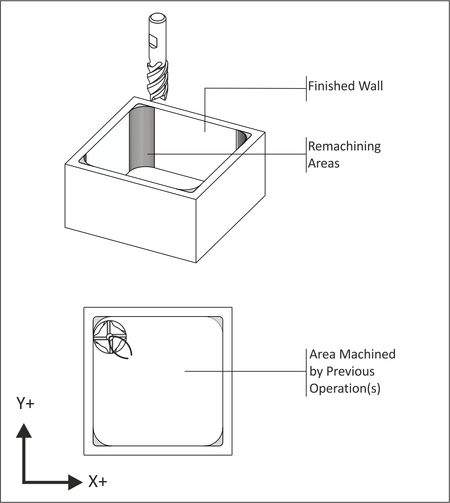

Figure 9.9: REST Milling |

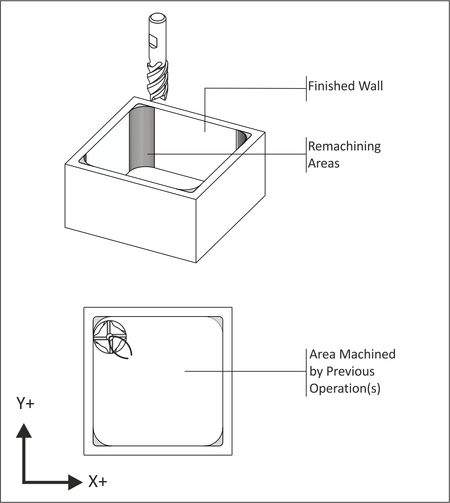

Rest Milling is an acronym for REmaining STock machining. Rest tool paths only remove material left by previous machining operations. They do this by calculating what stock has been previously removed and comparing it against the finished model. This is far more efficient than re-machining the entire part with a small tool just to create a few small features.

REST paths are calculation intensive. A good practice whenever possible is to use a tool whose diameter is slightly smaller than the smallest feature to be machined. This makes the REST calculations simpler and more effective.

|

|

Figure 9.9: REST Milling |