|

|

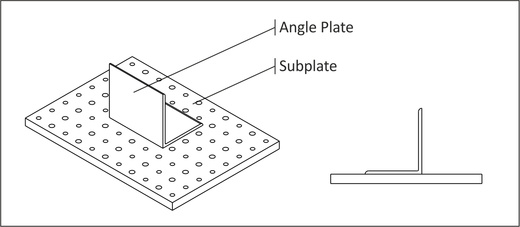

Figure 10.1: Angle Plate and Sub Plate |

There are many fixture components for milling machines. This section covers some of the most common. If possible, acquire a fixture components catalog or look at the web sites of Carr-Lane (www.carrlane.com), Jergens (www.jergensinc.com), Chick (www.chickworkholding.com), MSC (www.mscdirect.com) and others.

A Subplate is a ground aluminum plate that bolts to the top of the machine table. It has threaded holes and bushings at regular intervals.

Subplates protect the machine table and speeds setups by allowing clamps and other components to be quickly and precisely located anywhere in the workspace.

Once installed, the subplate generally remains permanently fixed on the table. Fixtures and vises are installed on top of it.

An Angle plate is a precision ground steel plate that allows the part to be set on its side. Angle plates can point in a direction parallel to either the X or Y axis.

|

|

Figure 10.1: Angle Plate and Sub Plate |

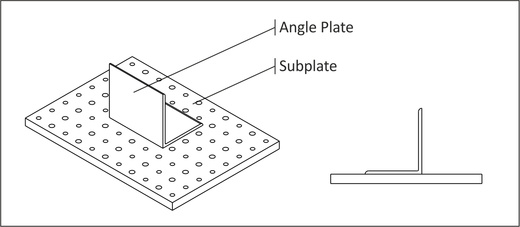

There are literally thousands of types, styles, and sizes of clamps available. They are inexpensive, reusable, and versatile. You tool cabinet should include many types and sizes of clamps and accessories.

|

|

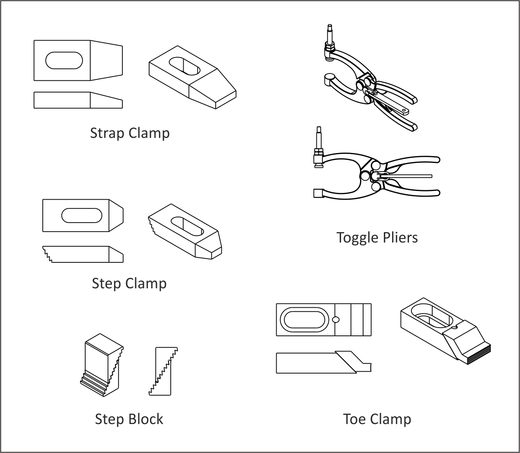

Figure 10.2: Clamps and Accessories |

Strap Clamps exert downward pressure on the part. They are usually secured to the table by a special bolt that can be positioned anywhere along the T-slots in the table. One end of the clamp rests on the part, and the other on a step block.

To prevent galling an aluminum part, place a pad of aluminum between the clamp and part.

Step blocks have grooves that allow them to be stacked to different heights. Step blocks are used to support one end of the strap clamp.

Step Clamps are similar to Strap clamps, but include grooves that interlock with a single step block.

Toe Clamps bolt to the machine table. The nose of the clamp includes grooves to grip the part. It is extended by turning a screw, forcing the clamp against the part and downward.

Toggle Pliers are similar to hardware store vise grip pliers.

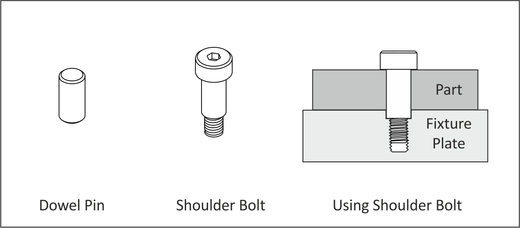

Dowel pins are used to precisely locate a part. They include a small chamfer to make insertion easier. Shoulder bolts both locate and grip the part. The ground shoulder on the bolt slides into a counterbore in the fixture.

|

|

Figure 10.3: Dowel Pin and Shoulder Bolt |