|

|

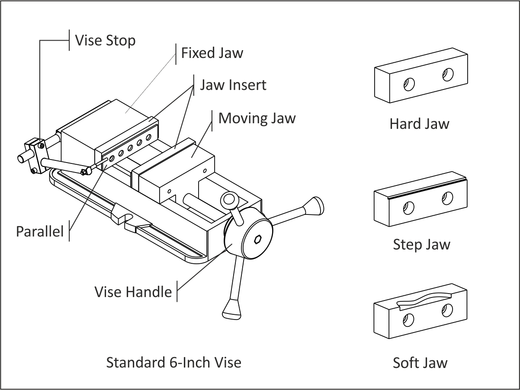

Figure 10.4: Vise and Accessories |

The CNC vise is precision engineered and manufactured with components ground flat and perpendicular to within .0002 inches. The most common is referred to as a six inch vise, because the width of the jaws is six inches.

Once the vise is bolted to the table and aligned, parts are loaded into the vise and clamped by closing the jaws. The vise can exert tremendous force, so care is taken not to over-tighten the vise and deform fragile parts. Vise pressure must be appropriate to the part being held and expected cutting forces.

|

|

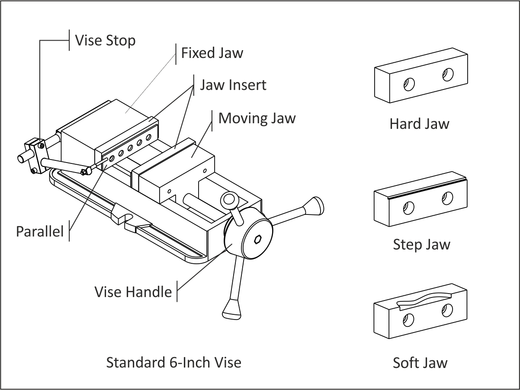

Figure 10.4: Vise and Accessories |

The Fixed Jaw remains stationary. The Moving Jaw opens when the Vise Handle is turned. It is a good practice to remove the vise handle after the jaws are closed and before running the program. This is done by simply sliding the handle off.

A Vise Stop is a device that allows the parts to be loaded into the vise precisely. This image shows a style of vise stop that is particularly useful because it is adjustable up-down and left-right.

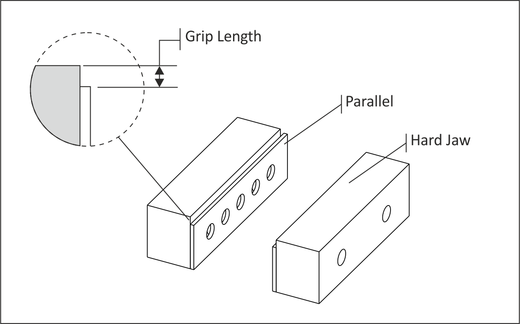

Hard Jaws are made of hardened steel and precision ground on all sides. They are usually used along with parallels.

Parallels are thin steel plates, available in various widths, used to set the grip length of the vise jaws.

|

|

Figure 10.5: Hard Jaws |

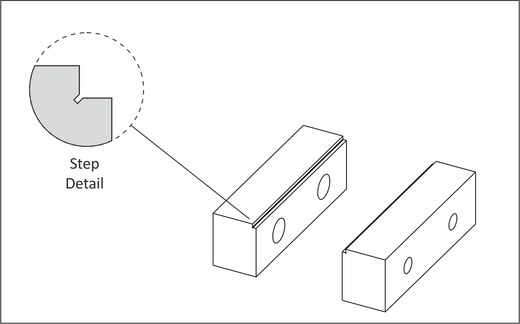

Step jaws are similar to hard jaws but include a step feature that eliminates the need for parallels.

|

|

Figure 10.6: Step Jaws |

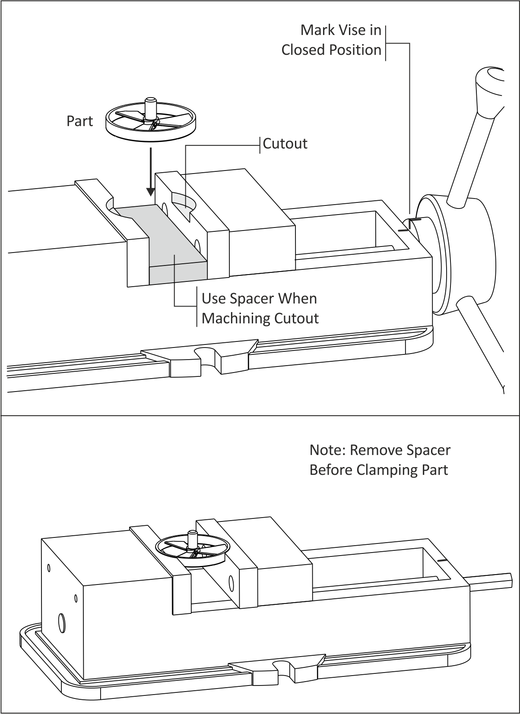

Soft jaws are blanks of aluminum used to grip parts that cannot be held using hard jaws. A cutout the same shape as the part is machined into the soft jaws to grip irregular shapes.

When machining the cutout, place a bar between the jaws to set the correct spacing. Use a torque wrench or mark the vise so it can be closed with the exact same pressure each time a new part is loaded. Remove the spacer before clamping the part.

|

|

Figure 10.7: Machining Soft Jaws |