Collection types

Automatic data collection

Machine data is collected automatically and unattended through a network. When a machine event occurs, such as starting or stopping, the signals associated with those events are sent to MDC-Max, stored and processed for further use.

Manual data collection

Operator data provides the context needed to fully understand reasons for downtime, scrap or other negative factors. For manual data collection, MDC-Max provides an operator interface for PC and mobile devices. It also comes with full support for barcode readers.

Interfaces

Operator Screen

Enables operators to access vital information and enter reasons for downtime, scrap, current job/operator/shift, and more. Can be customized and accessed with a mobile device or PC. One device can manage several machine-specific Operator Screens. Operator tablets can also be mounted at every machine.

Barcode readers

Enables operators to scan a barcode to provide reasons for downtime, scrap, current job/operator/shift, and more. MDC-Max can generate and print barcodes. Mostly relevant if barcode readers are already available. Otherwise, we recommend using Operator Screens.

Initial setup

Start small

More data does not always equal more value and an MDC system always requires new workflows and training. The best way to succeed, is to start small and get the easy benefits by analyzing only three to five data points. With more experience, the system can be expanded. See examples below for inspiration.

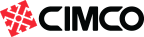

1. Production vs. downtime

This solution gives data about the production or downtime of a machine. Data is collected automatically from the machine, so a supervisor needs to ask the operator the reason for the machine stoppage to get more information.

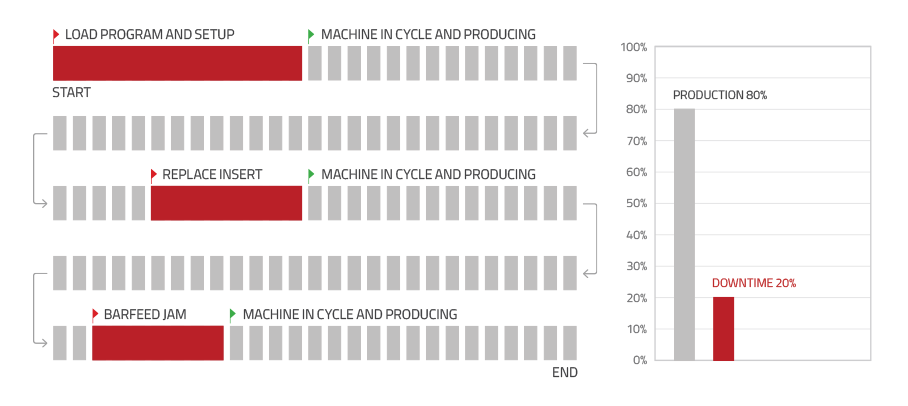

2. Downtimes in more detail

This solution accurately shows a machine’s efficiency on every job. We can show the total downtime percentage for each type of stoppage such as Tooling, Setting, Maintenance, etc. The operator enters the reasons for downtime using an Operator Screen or a barcode reader which can then help identify the exact causes of production loss.

Example

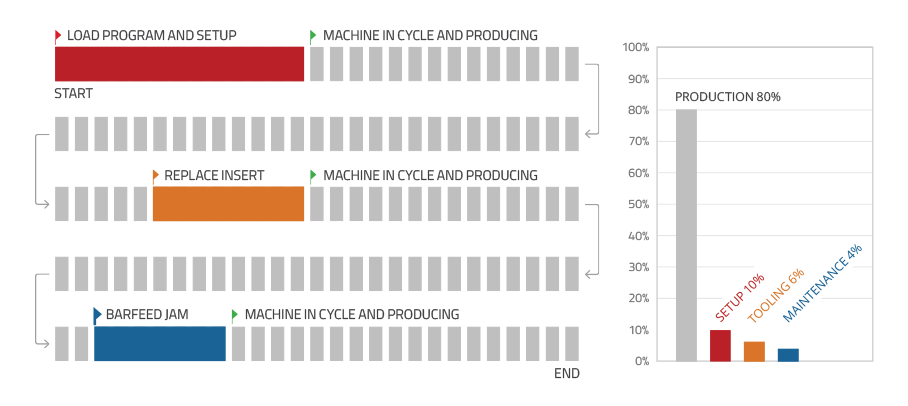

Elements in a setup

The following diagram shows a simplified MDC setup with data collection from machines and operators.

Machine signals and operator feedback are sent to MDC-Max through the local network using wireless and Ethernet.

Each machine has a tablet with the Operator Screen application or a barcode reader to provide data. A operator has a smartphone where he can provide data about any machine in the setup. He just opens the Operator Screen on his phone for the specific machine he is at.

A legacy machine has been connected with a serial connection to the Ethernet network (and some internal wiring) to track start and stop signals.