Connections

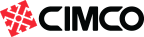

MDC-Max uses a network to establish connections and collect data from equipment. Often a company’s exiting local network is used, but in some cases a dedicated, closed network is preferred. Depending on the machines’ data collection capabilities, different approaches are possible.

Direct connection

If a data interface is available on the machine (see table below), it can often be connected to a network via an Ethernet cable. No additional hardware is required beyond optional devices for operator input such as a mounted tablet. However, if the interface is disabled on the machine control, it can be costly to activate. In this case, a Hardware connection might be preferred.

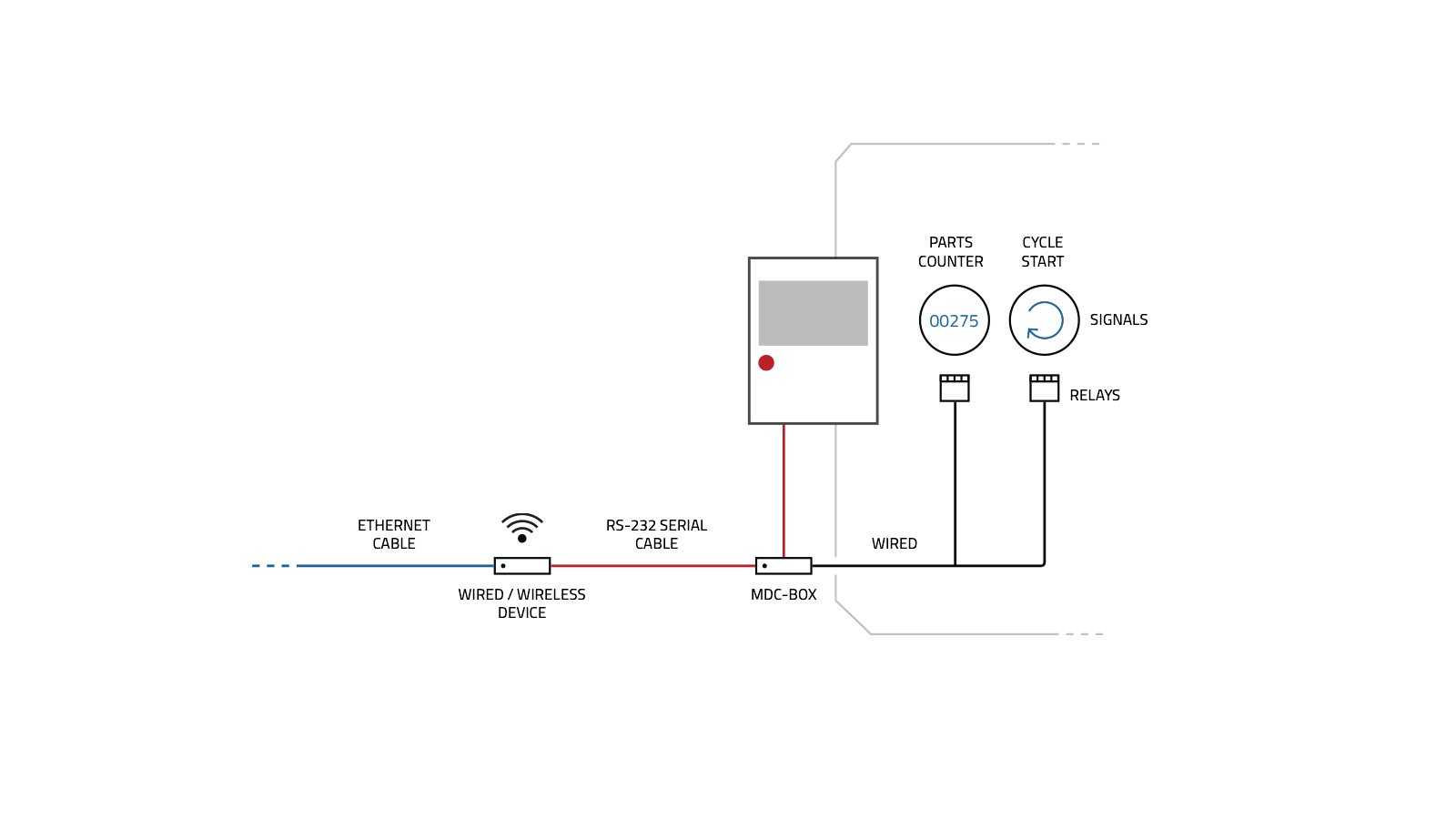

Hardware connection

If no interface is available, a technician can “pull” signals from the machine using a combination of internal wiring to PLC relays and devices such as an MDC-Box or the Moxa ioLogik. These devices manage the connection between the machine and network, and facilitate signal transmission to MDC-Max.

Supported controls

For direct connections, MDC-Max supports a wide variety of machine controls. The following are some of the most common, but many more are supported. If your control is not listed, please contact us for more information. We are continuously adding support for new machines.

| Control | Required interface | Extent of data access |

|---|---|---|

| Fanuc | FOCAS | Full compatibility |

| Haas | M-Net | Full compatibility |

| Mazak | MTConnect | Full compatibility |

| Okuma | MTConnect | Full compatibility |

| Mitsubishi | MTConnect | Full compatibility |

| NUM | MTConnect | Full compatibility |

| Heidenhain | DNC Opt #18 | Full compatibility |

| Siemens (840D, 810D) | Hardware adapter | Most compatibility |