Reports

Custom reports

MDC-Max can generate custom real-time and historic reports from the data it collects. Data can be presented as tables, pie or bar charts, and production targets, work shifts, KPIs, and more can be included. You can also generate different Event logs such as by operator, machine, and job to check how each machine and operator is doing. Examples of other reports:

- Cycle time per part (min, max and average)

- Number of parts per shift/operator

- Number of scrapped parts

- Machine downtime

- Scheduled maintenance

- Unscheduled maintenance

- Setup time per part

- Operator effectiveness

- Overall Equipment Effectiveness (OEE)

- Mean time between failures (MTBF)

- Mean time to repair (MTTR)

Examples

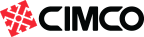

Cycle time, duration and deviation

For each part in a job we can see the cycle start and stop times, duration and deviation (%) from the planned cycle time.

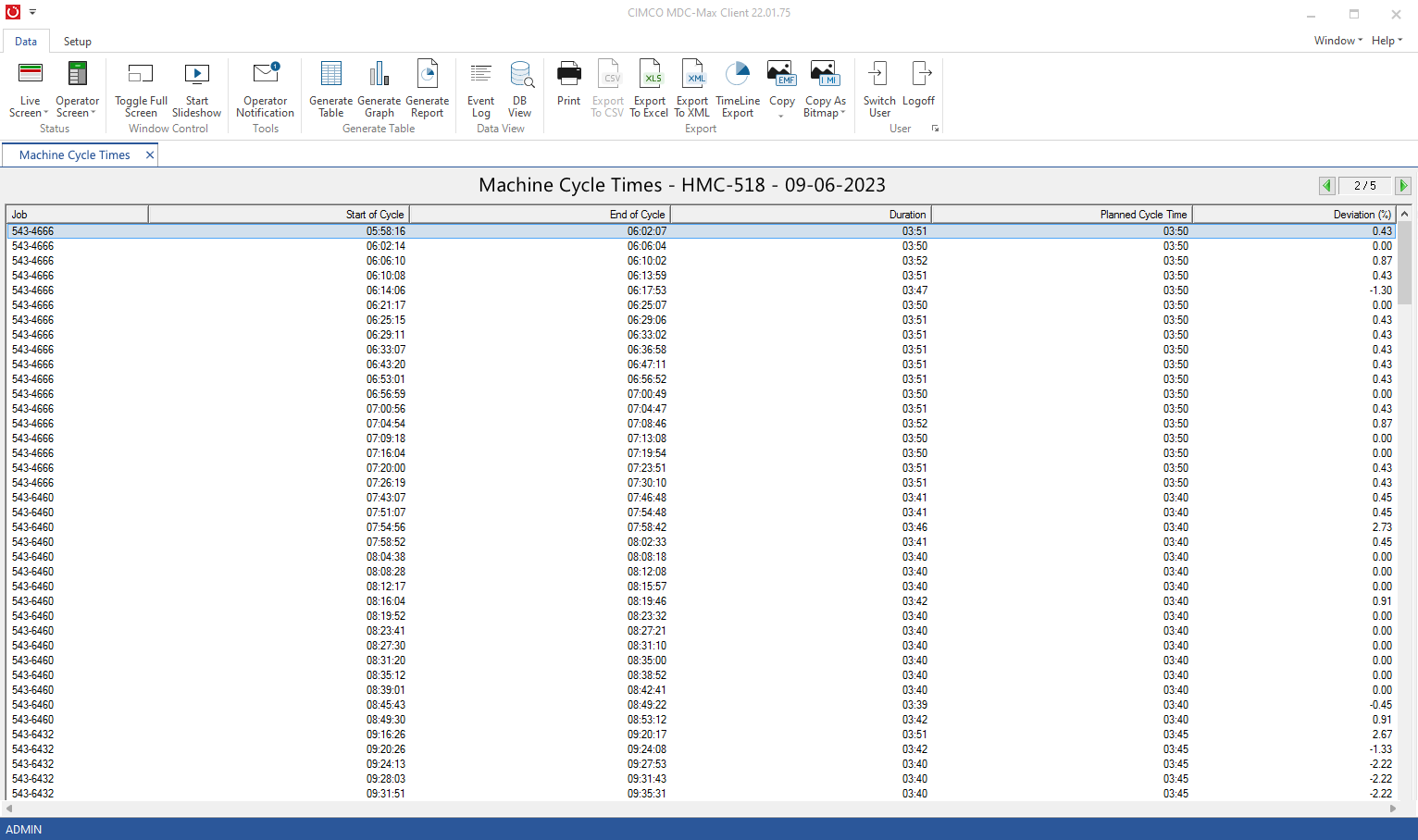

Machine utilization as timeline

Each timeline shows the exact machine status during the selected time frame and dynamically update at a set interval to include new data.

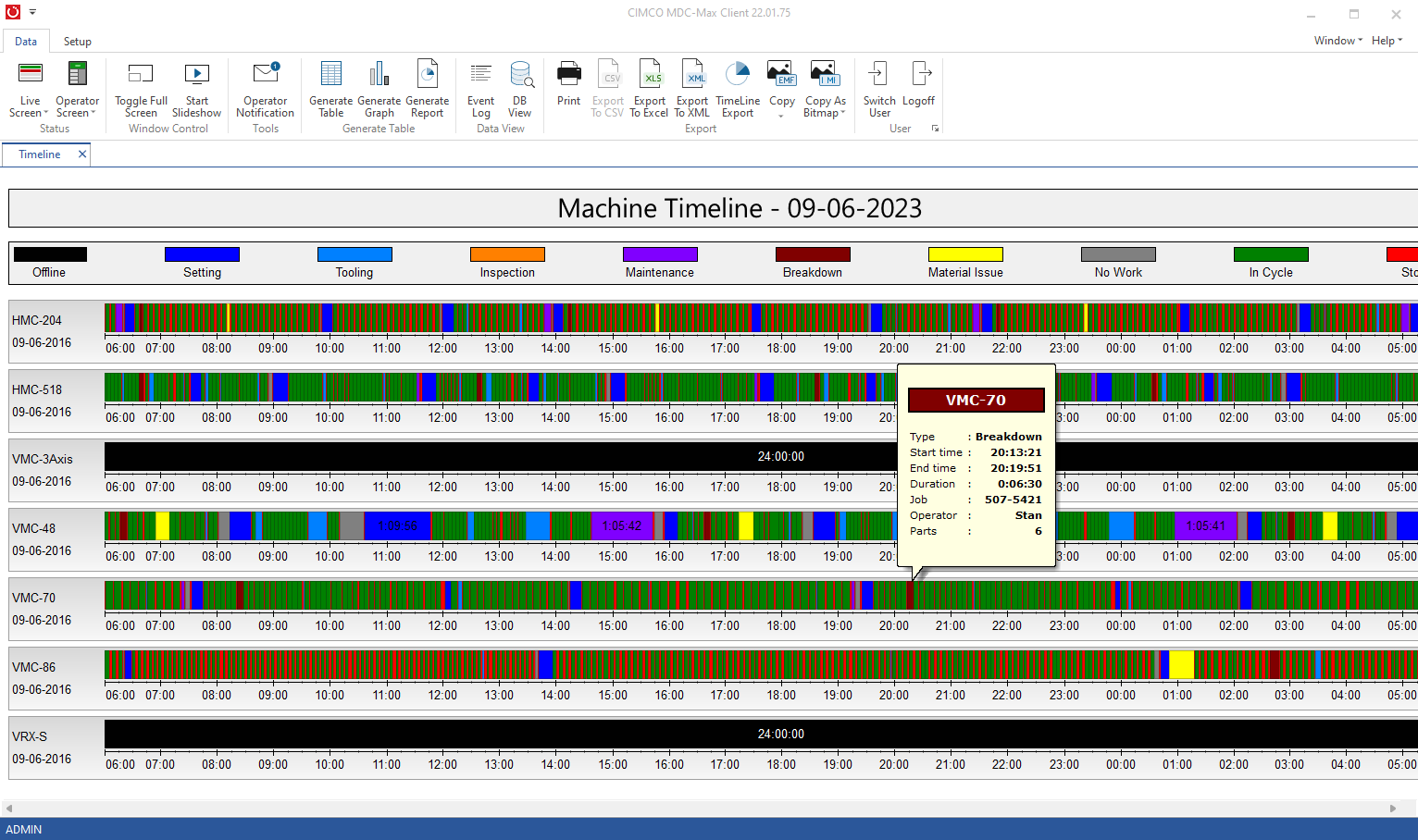

Productivity summary chart

Summarized utilization in percent and visualized as Pie charts. Makes it easy to see how each machine is doing.

Machine utilization with target

Bar chart showing machine utilization in percent over a 24 hour time period. Target and Minimum values added.

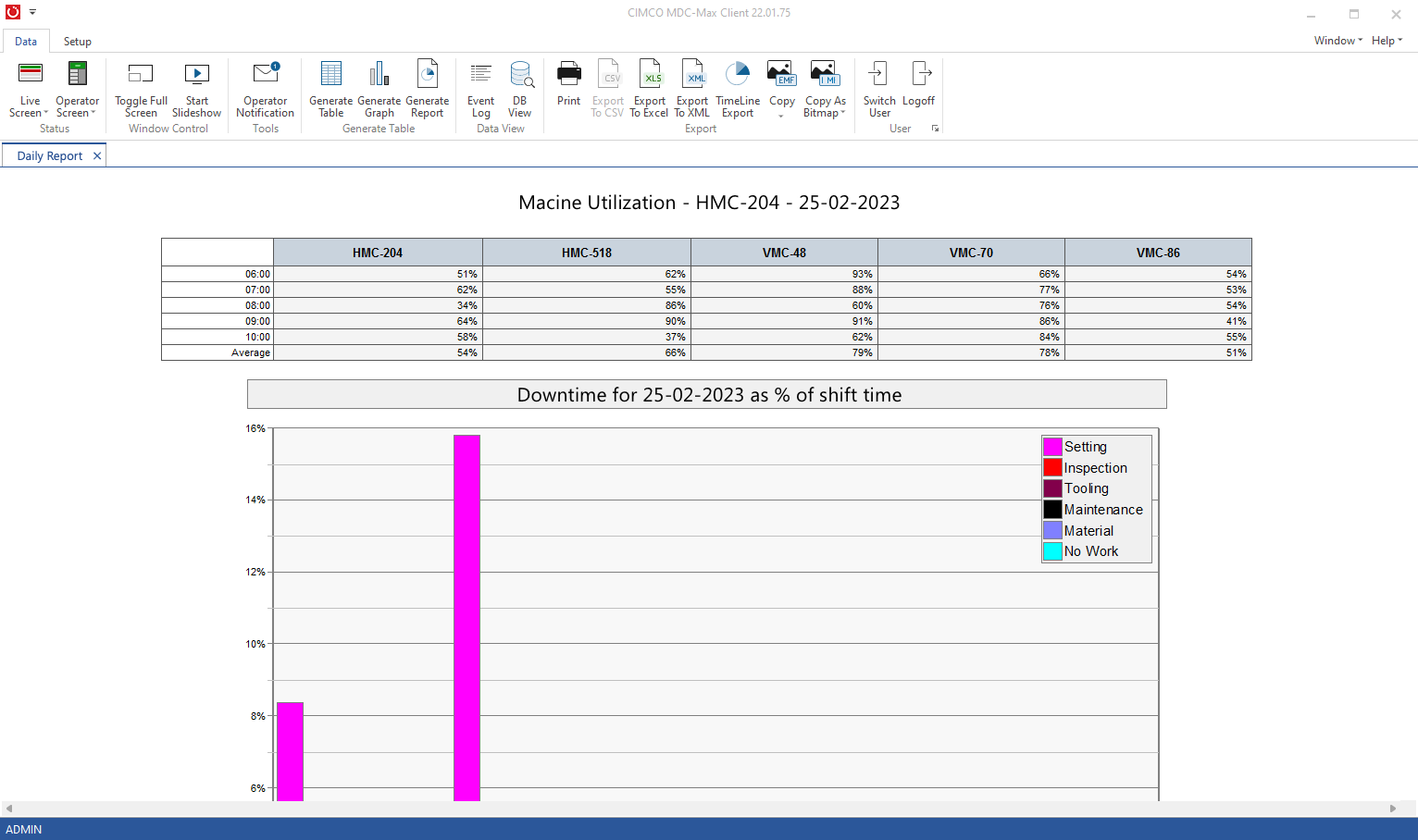

Daily overview

Overview of utilization for several machines and downtime as a percentage of the total shift time.

Microsoft Excel

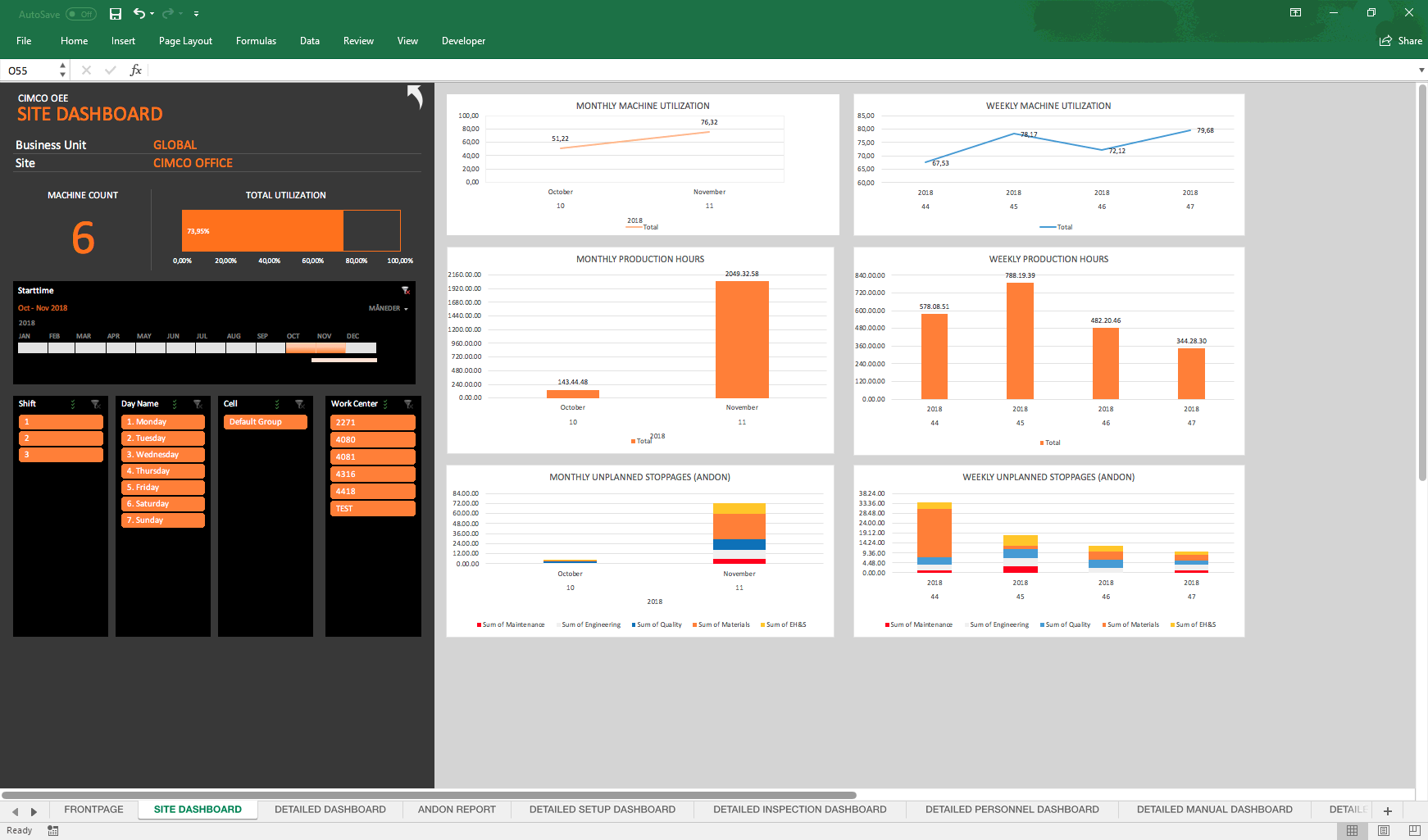

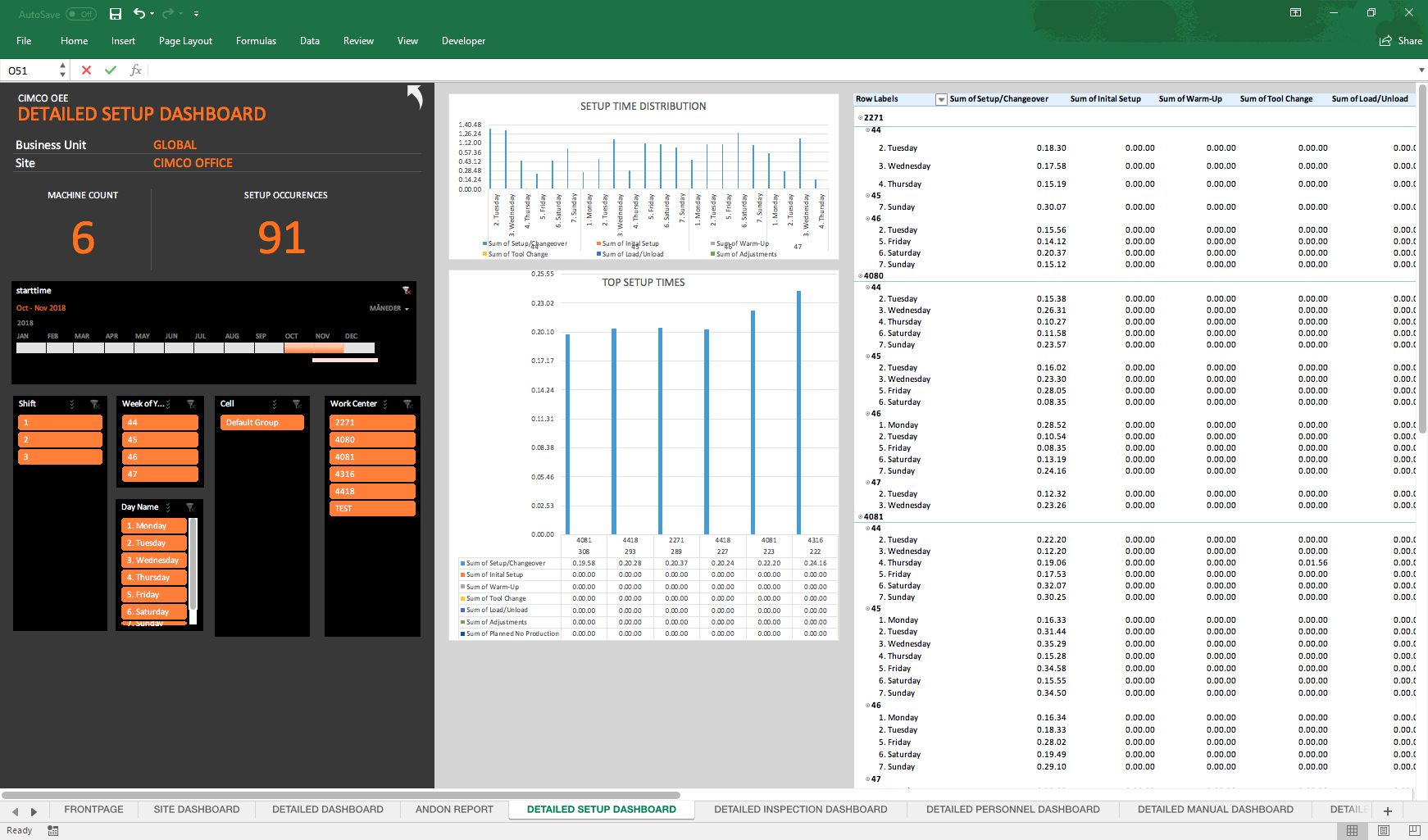

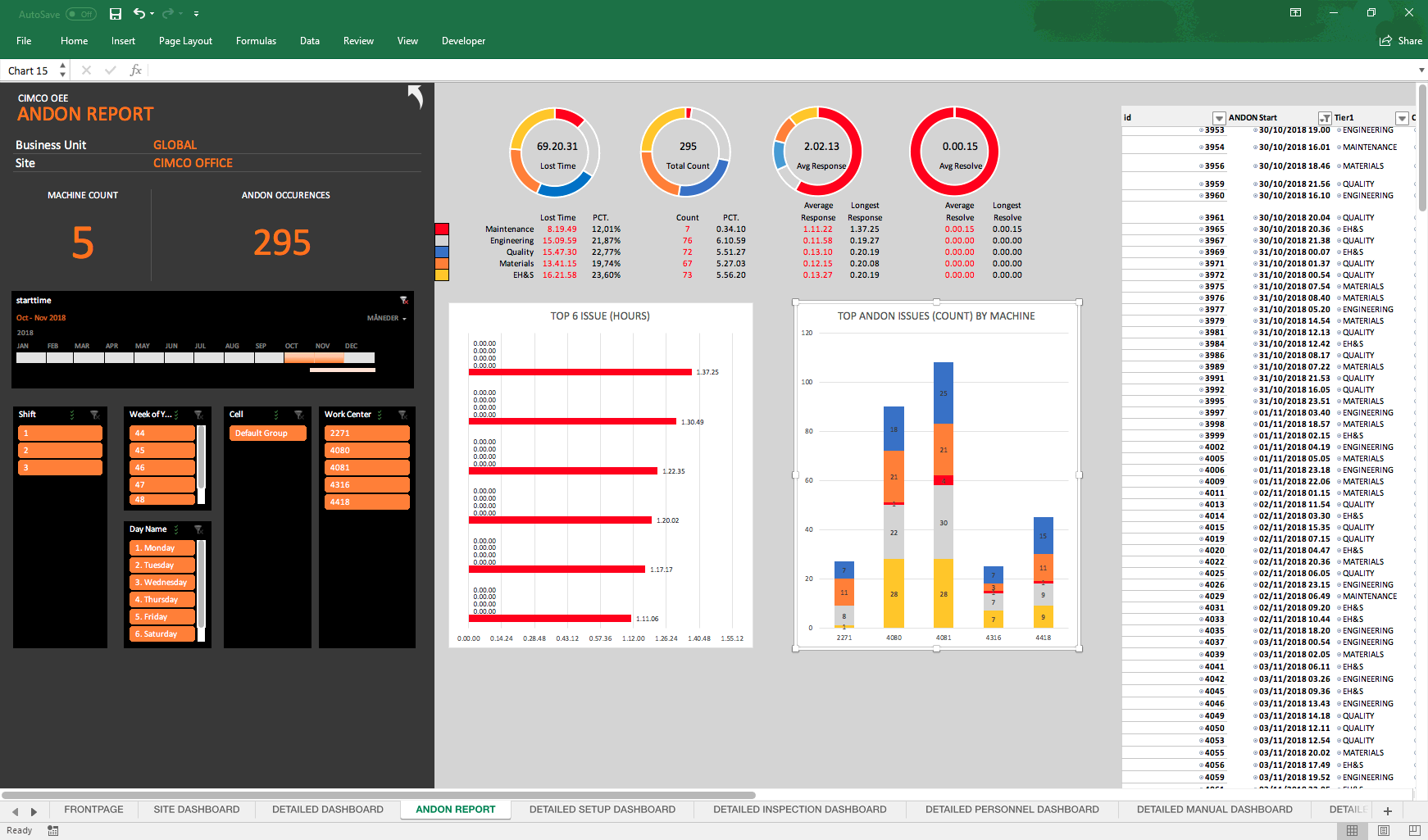

Stand-alone Reports in Excel

Stand-alone reports provides a direct and convenient way for authorized users to access and update MDC-data in Excel reports without using MDC-Max. Reports can take advantage of all the built-in functionality that Excel has to offer such as Column-, Line-, Pie-, and Bar Charts. Once a report is configured, Excel provides the flexibility to filter data by machine(s), operator(s), time period, and more.

Export report data to Excel

MDC-Max can also export the data of any configured report to Excel. This enables you to generate and view reports in MDC-Max and export the same data for further analysis in Excel.

Site Dashboard

Detailed Setup Dashboard

Andon Report

Export reports to Word or PDF

Integration

MDC-Max provides several ways to automate processes and exchange data with a company’s existing software systems such as an MRP, ERP or MES.

Transfer data to external systems

On specific events or conditions, MDC-Max can transfer or update data in external data sources such as a database or web service. Data can also be exported and transfered in several formats such as XML and JSON.

External access to MDC-Max database

MDC-Max can authorize external systems to pull data directly from its database (read/write/update). Can normally be configured using the standard Open Database Connectivity API (ODBC).

Further integration and automation

MDC-Max also provides the OEMLink C++ library which can be programmed to “catch” incomming data events and trigger custom code to call a web service, export data, call up external APIs, and more.